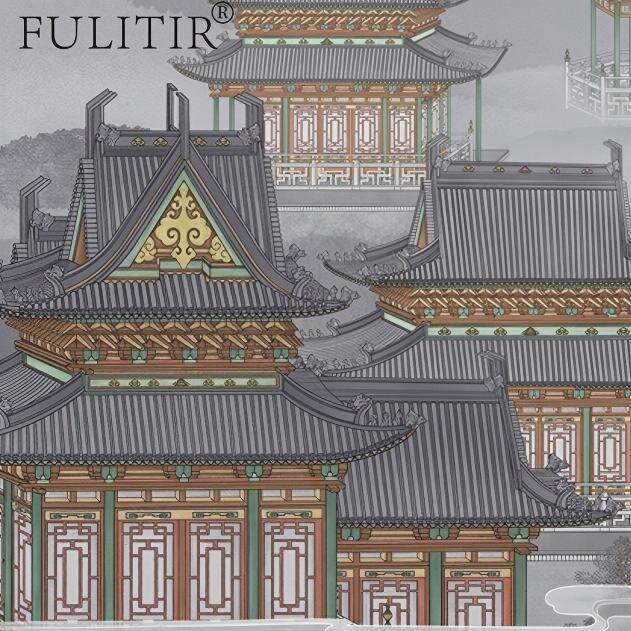

When creating stunning visual displays for exterior spaces, selecting the right ink technology becomes crucial for ensuring your outdoor printing murals maintain their vibrant appearance over time. The harsh outdoor environment presents unique challenges including UV radiation, temperature fluctuations, moisture exposure, and atmospheric pollutants that can rapidly degrade inferior ink formulations. Understanding which ink types offer superior longevity will help you make informed decisions for your next outdoor advertising campaign or architectural enhancement project. Professional outdoor printing murals require specialized ink chemistry that can withstand these environmental stresses while delivering exceptional color reproduction and fade resistance.

Understanding Ink Longevity Factors in Outdoor Applications

Environmental Stress Impact on Ink Performance

The outdoor environment subjects outdoor printing murals to multiple degradation mechanisms that indoor graphics never encounter. Ultraviolet radiation breaks down molecular bonds in ink pigments and dyes, causing color shifts and fading over time. Temperature cycling creates expansion and contraction stress within the ink layer, potentially leading to cracking or delamination from the substrate. Moisture infiltration can cause ink bleeding, substrate warping, and promote mold or mildew growth that compromises visual quality.

Atmospheric pollutants including acid rain, industrial emissions, and salt spray in coastal areas accelerate chemical degradation processes. These contaminants react with ink components, causing discoloration, surface etching, and premature deterioration. Wind-borne abrasives like dust and sand create micro-scratches that compromise the protective ink surface, allowing deeper penetration of damaging elements. Understanding these environmental factors helps explain why specialized outdoor formulations significantly outperform standard indoor inks.

Substrate Interaction and Adhesion Properties

The interaction between ink and substrate materials plays a critical role in determining the lifespan of outdoor printing murals. Different substrate materials exhibit varying thermal expansion rates, porosity levels, and surface energy characteristics that affect ink adhesion and flexibility. Proper ink-substrate compatibility ensures the printed image moves uniformly with the base material during temperature changes, preventing stress-related failures.

Surface preparation and primer application significantly influence long-term adhesion performance. Inadequate surface cleaning or improper primer selection can create weak interfaces that fail under outdoor stress conditions. The chemical composition of the substrate also affects ink compatibility, with some materials requiring specialized adhesion promoters or surface treatments to achieve optimal bonding strength for extended outdoor exposure.

Solvent-Based Ink Systems for Maximum Durability

Eco-Solvent Technology Advantages

Eco-solvent inks represent the gold standard for outdoor printing murals requiring exceptional longevity and environmental resistance. These formulations combine organic pigments with low-volatility solvent carriers that penetrate deeply into substrate materials, creating superior mechanical adhesion compared to surface-based alternatives. The solvent component evaporates completely during the curing process, leaving behind a durable pigment matrix that resists environmental degradation.

Modern eco-solvent systems incorporate advanced lightfast pigments specifically selected for their UV stability and color retention properties. These pigments maintain their molecular structure when exposed to intense solar radiation, preventing the color shifts and fading common with inferior ink technologies. The resulting prints typically achieve fade resistance ratings of 3-5 years for outdoor applications, making them ideal for commercial signage and architectural graphics.

Mild Solvent Formulation Benefits

Mild solvent inks offer enhanced safety profiles while maintaining excellent outdoor durability characteristics for outdoor printing murals. These formulations utilize lower-odor solvent systems that reduce workplace exposure concerns while still providing deep substrate penetration and superior adhesion properties. The reduced solvent content also minimizes environmental impact during production and installation processes.

The curing characteristics of mild solvent inks allow for faster production throughput while ensuring complete solvent evaporation for optimal durability. These systems often incorporate specialized resin components that enhance flexibility and impact resistance, critical properties for outdoor applications subjected to thermal cycling and mechanical stress. Color gamut performance remains excellent, with many mild solvent systems achieving wider color reproduction than traditional solvent alternatives.

UV-Curable Ink Technology for Outdoor Excellence

Instant Curing Performance Characteristics

UV-curable inks provide exceptional durability for outdoor printing murals through their unique polymerization curing mechanism. When exposed to UV light, these inks undergo rapid cross-linking reactions that create a highly durable polymer network resistant to environmental degradation. This instant curing process eliminates solvent evaporation time and produces prints ready for immediate outdoor installation.

The polymer matrix formed during UV curing exhibits superior chemical resistance compared to conventional dried ink films. This enhanced chemical stability protects outdoor printing murals from acid rain, industrial pollutants, and cleaning chemicals commonly encountered in urban environments. The resulting surface hardness also provides excellent abrasion resistance against wind-borne particles and routine maintenance activities.

Pigment Encapsulation and Protection

UV-curable ink systems encapsulate pigment particles within the polymerized matrix, providing exceptional protection against UV-induced fading and color degradation. This encapsulation mechanism prevents direct pigment exposure to oxygen and environmental contaminants that accelerate deterioration processes. The result is outstanding color stability and fade resistance, with properly formulated UV inks achieving 5-7 year outdoor longevity ratings.

Advanced UV ink formulations incorporate specialized UV absorber additives that provide additional protection against harmful radiation wavelengths. These additives sacrifice themselves to prevent UV damage to the underlying pigments and polymer matrix, extending the effective lifespan of outdoor printing murals beyond what standard formulations can achieve. The combination of physical encapsulation and chemical protection creates extremely robust outdoor graphics suitable for long-term architectural applications.

Latex Ink Systems for Environmental Sustainability

Water-Based Formulation Advantages

Latex ink technology offers environmentally responsible solutions for outdoor printing murals without compromising durability performance. These water-based systems eliminate volatile organic compound emissions while delivering excellent outdoor longevity through advanced polymer chemistry. The latex particles form continuous films during the drying process, creating weather-resistant barriers that protect underlying pigments from environmental degradation.

Modern latex formulations incorporate high-performance pigments and polymer resins specifically engineered for outdoor applications. These systems achieve impressive fade resistance and weather stability while maintaining workplace safety and environmental compliance. The absence of hazardous air pollutants makes latex inks ideal for installations in sensitive environments or areas with strict emission regulations.

Thermal Film Formation Properties

The unique curing mechanism of latex inks involves thermal film formation where polymer particles coalesce under controlled heat application. This process creates seamless, continuous films with excellent barrier properties against moisture and atmospheric contaminants. The resulting surface exhibits superior flexibility and crack resistance, critical characteristics for outdoor printing murals subjected to thermal cycling.

Latex ink films demonstrate excellent adhesion to diverse substrate materials through mechanical interlocking and chemical bonding mechanisms. The polymer chains penetrate into porous substrates while forming chemical bonds with suitable surface treatments. This dual adhesion mechanism ensures long-term durability even under severe outdoor exposure conditions including freeze-thaw cycles and extreme temperature variations.

Pigment Selection and Color Stability Considerations

Lightfast Pigment Classification Systems

The selection of appropriate pigments fundamentally determines the longevity of outdoor printing murals exposed to solar radiation. Lightfastness ratings, typically measured on scales from 1-8, indicate a pigment's resistance to UV-induced fading under standardized exposure conditions. Professional outdoor applications require pigments with lightfastness ratings of 6 or higher to ensure acceptable color retention over multi-year exposure periods.

Organic pigments generally offer superior color vibrancy and saturation compared to inorganic alternatives but may exhibit lower lightfastness ratings. Inorganic pigments, while sometimes limited in color gamut, provide exceptional UV stability and weather resistance. Modern ink formulations often combine both pigment types strategically to optimize color performance and durability characteristics for specific outdoor applications.

Color Metameric Considerations

Metamerism effects can significantly impact the perceived color stability of outdoor printing murals under varying illumination conditions. Colors that match perfectly under controlled lighting conditions may appear different under natural sunlight, fluorescent lighting, or artificial illumination. Understanding metameric behavior helps predict how colors will appear throughout different times of day and weather conditions.

Spectral reflectance characteristics of pigments determine their metameric behavior and overall color stability. High-quality outdoor printing murals utilize pigments with smooth, consistent spectral curves that minimize metameric shifts under changing illumination conditions. This consideration becomes particularly important for corporate branding applications where color consistency across different viewing conditions is critical for brand recognition.

Substrate Material Impact on Ink Longevity

Synthetic Fabric Performance Characteristics

The choice of substrate material significantly influences the achievable lifespan of outdoor printing murals regardless of ink selection. Synthetic fabrics such as polyester and vinyl offer excellent dimensional stability and chemical resistance compared to natural fiber alternatives. These materials resist moisture absorption, preventing substrate degradation that can compromise ink adhesion and visual quality over time.

Woven and knit fabric constructions provide different performance characteristics for outdoor applications. Woven fabrics typically offer superior tear resistance and dimensional stability, making them ideal for large-format outdoor printing murals exposed to wind loading. Knit constructions provide enhanced flexibility and conformability around curved surfaces but may exhibit greater stretch and distortion under environmental stress.

Rigid Substrate Durability Factors

Rigid substrate materials including aluminum composites, PVC sheets, and polycarbonate panels provide stable printing surfaces for outdoor printing murals requiring maximum longevity. These materials eliminate concerns about fabric stretching, sagging, or wind-induced movement that can stress printed ink films. The dimensional stability of rigid substrates ensures consistent ink film integrity throughout extended outdoor exposure periods.

Surface treatments and coatings on rigid substrates directly affect ink adhesion and long-term performance. Specialized primers and adhesion promoters create optimal bonding surfaces for different ink technologies while providing additional UV and chemical resistance. Proper surface preparation protocols ensure maximum adhesion strength and prevent delamination failures that compromise outdoor graphics durability.

Installation and Maintenance Best Practices

Environmental Exposure Management

Proper installation techniques significantly extend the service life of outdoor printing murals regardless of ink technology selection. Strategic positioning to minimize direct UV exposure during peak sunlight hours can substantially reduce photodegradation rates. South-facing installations experience the most severe UV exposure, while north-facing orientations receive primarily diffused light that causes less ink degradation over time.

Wind loading considerations affect both substrate selection and mounting system design for outdoor printing murals. Excessive substrate movement creates stress concentrations in ink films that can lead to cracking or delamination. Proper tensioning systems and adequate mounting point spacing ensure substrate stability while allowing for thermal expansion and contraction cycles.

Preventive Maintenance Protocols

Regular cleaning and inspection programs dramatically extend the lifespan of outdoor printing murals by removing accumulated contaminants before they cause permanent damage. Gentle cleaning solutions and soft brushes prevent surface scratching while effectively removing dirt, pollutants, and biological growth. Quarterly inspections identify early signs of degradation that can be addressed before major repairs become necessary.

Protective coating applications provide additional barriers against environmental degradation for high-value outdoor printing murals. Clear overlamination films or liquid coatings shield ink surfaces from direct UV exposure and physical abrasion. These protective systems require periodic replacement but significantly extend the underlying graphic lifespan and maintain visual quality throughout extended outdoor service.

FAQ

What ink type provides the longest outdoor lifespan for printing murals

UV-curable inks typically provide the longest outdoor lifespan for printing murals, with properly formulated systems achieving 5-7 years of fade resistance under normal outdoor conditions. The instant polymerization curing process creates exceptionally durable polymer networks that resist environmental degradation better than solvent-based or latex alternatives. However, eco-solvent systems also offer excellent 3-5 year outdoor performance with easier handling and installation requirements.

How does substrate material selection affect outdoor mural durability

Substrate material selection critically impacts outdoor mural durability by affecting ink adhesion, dimensional stability, and environmental resistance. Synthetic materials like polyester fabrics and vinyl substrates provide superior moisture resistance and UV stability compared to natural fiber alternatives. Rigid substrates eliminate concerns about fabric movement and stretching but require specialized mounting systems to accommodate thermal expansion and contraction cycles.

Can protective coatings extend the lifespan of outdoor printing murals

Yes, protective overlamination films and liquid coatings can significantly extend outdoor printing mural lifespan by providing additional UV protection and abrasion resistance. Clear protective films typically add 1-2 years to the effective service life while liquid coatings offer renewable protection through periodic reapplication. These systems require additional investment but prove cost-effective for high-value installations requiring maximum longevity.

What environmental factors cause the most damage to outdoor printing murals

UV radiation represents the most significant environmental threat to outdoor printing murals, causing photodegradation of pigments and polymer matrices that leads to fading and color shifts. Temperature cycling creates expansion and contraction stress that can cause ink film cracking or substrate delamination. Moisture exposure and atmospheric pollutants also accelerate degradation processes, making comprehensive environmental protection essential for maximum durability.

Table of Contents

- Understanding Ink Longevity Factors in Outdoor Applications

- Solvent-Based Ink Systems for Maximum Durability

- UV-Curable Ink Technology for Outdoor Excellence

- Latex Ink Systems for Environmental Sustainability

- Pigment Selection and Color Stability Considerations

- Substrate Material Impact on Ink Longevity

- Installation and Maintenance Best Practices

- FAQ